First of all there are several main causes of Turbocharger failure:

Oil lubrication:

In order for your turbocharger to work effectively it needs a regular flow of good clean oil to keep your turbocharger in the best condition possible. Always be sure to change your oil and oil filter frequently to keep your turbocharger in good health. By doing so you help to prevent the build up of carbon deposits and other sorts of contaminants that can cause damage. Fully synthetic oil actually produces the least amount of carbon.

Foreign objects:

Sometimes you can get foreign objects like broken components from the engine, small stones, dust particles etc which can enter the turbocharger from either the compressor inlet or the turbine inlet.

These can cause damage to the compressor wheels and also the turbine blades which will start to reduce the efficiency of the turbocharger and eventually cause it to fail. To prevent this from happening always be sure to service your air filter regularly and that you check your turbocharger for any deposits or particles that may be in there.

Other causes:

In addition to the causes mentioned above, over-speeding can also cause turbocharger failure, wear and tear, excessive exhaust gas temps, issues with the actuator etc.

So what are the warning signs of Turbocharger failure?

Engine warning lights:

Most vehicles these days have computer diagnostics which will pick up the turbo fault and will activate the engine management light. The engine management light can come on for any number of reasons so will you need to investigate further to find out what is going on.

Power loss:

If you notice that your vehicle isnt reaching the speeds it normally does or isnt accelerating the way it should then this could be a sign of your turbocharger wearing out.

Exhaust smoking:

If there is a crack in the turbo housing or the internal seals have broken, then you will start to get oil leaking into the exhaust system. As this oil starts to burn, it will produce grey / blue smoke which will be more obvious as the engine revs increase.

Loud whining noise:

It can be quite common for a turbocharger that is failing to begin making a loud whining noise. If you start to hear this sort of noise coming from your engine bay then its a good shout to get it checked out.

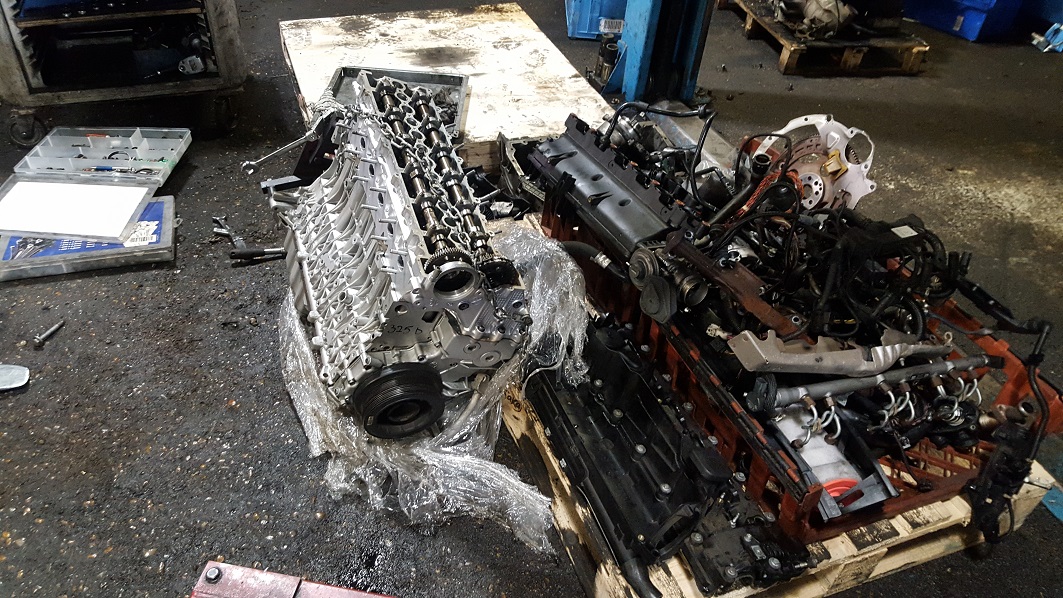

Checking your turbo:

So you’ve noticed that some of the above symptoms are happening to you, so what do I do? Well, if your technically minded and dont mind getting your hands dirty then you can check for a range of faults by yourself by inspecting the turbocharger.

Before you get started, be sure to check the air filter, exhaust system, breather system and fuel system to make sure they are all working properly without any problems as these can cause similar symptoms to that of turbocharger failure.

So essentially what you’re looking for are signs of oil inside the turbo, excessive movement or contact between the compressor wheel and the housing. The compressor wheel should be clean, without any chips, or dents. You need to check to see that the wheel is able to rotate freely without too much movement and without making contact to the housing.

From the turbine side, it should be clean without carbon build up or oil along the surface and the blades should not have any cracks or damage. Again there should not be excessive movement or contact with the housing.

Here are a number of examples of turbochargers which failed on our customers vehicles. We always make a practice to send our clients either videos or photos of components which have failed so that they can have a better understanding themselves of what exactly is going on.

This first video shows a turbocharger which was faulty due to excessive movement in the wheel. As you can see it was far too loose:

In this second example, although the turbocharger wasnt showing too much sign movement, you can see that it wasnt moving freely and this was due to the wheel making contact with the housing.

In this final example it is the turbocharger actuator arm that is extremely stiff and making a loud noise when attempted to move by hand.

With every one of the above examples, we sent the video to our clients so that they can visibly understand the problem.

If you feel you are experiencing turbocharger failure or just need some general advice, please feel free to get in touch with one our members of staff on 0208 133 6004